Difference between revisions of "Furnace"

From Unofficial Stationeers Wiki

Dr nerdrage (talk | contribs) m |

(Proper temperature/pressure values for recipes, correct gas mix ratio note) |

||

| Line 21: | Line 21: | ||

<!--T:4--> | <!--T:4--> | ||

| − | + | While smelting steel is easily achieved with ice, other recipes usually require a working piping setup. This can be done by separating gases into tanks using atmospheric units and piping individual gases through a mixer and a pressure regulator or a volume pump connected to the furnace input. Output should also be extracted and vented/recycled through a backpressure regulator to keep furnace pressure in check. The optimal gas mix that burns completely is 1 part (33.3%) oxygen to 2 parts (66.6%) volatiles, other mixes would also work but leave you with leftover oxygen or volatiles depending on the percentages used. It could also result in lower temperature if that is desired, but you could also use a volume pump with a lower fuel input setting. | |

{| class="wikitable" | {| class="wikitable" | ||

!Metal | !Metal | ||

!Components | !Components | ||

| − | ! | + | !Minimum Temperature |

| − | ! | + | !Maximum Temperature |

| − | ! | + | !Minimal Pressure |

| + | !Maximum Pressure | ||

!Notes | !Notes | ||

|- | |- | ||

|[[Steel Ingot]] | |[[Steel Ingot]] | ||

|3 iron / 1 coal | |3 iron / 1 coal | ||

| − | | | + | |600 |

| − | | | + | |— |

| − | | | + | |100kPa |

| + | |— | ||

|Can easily be achieved by just dropping 1 oxite and 2 volatiles | |Can easily be achieved by just dropping 1 oxite and 2 volatiles | ||

|- | |- | ||

|[[Electrum Ingot]] | |[[Electrum Ingot]] | ||

|1 gold / 1 silver | |1 gold / 1 silver | ||

| − | | | + | |700 |

| − | | | + | |10000 |

| − | | | + | |800kPa |

| + | |2400kPa | ||

| | | | ||

|- | |- | ||

|[[Solder Ingot]] | |[[Solder Ingot]] | ||

|1 iron / 1 lead | |1 iron / 1 lead | ||

| − | | | + | |300 |

| − | | | + | |2000 |

| − | | | + | |300kPa |

| + | |3500kPa | ||

| | | | ||

|- | |- | ||

|[[Constantan Ingot]] | |[[Constantan Ingot]] | ||

|1 copper / 1 nickel | |1 copper / 1 nickel | ||

| − | | | + | |1000 |

| − | | | + | |1500 |

| − | | | + | |100kPa |

| + | |10000kPa | ||

| | | | ||

|- | |- | ||

|[[Invar Ingot]] | |[[Invar Ingot]] | ||

|1 iron / 1 nickel | |1 iron / 1 nickel | ||

| − | | | + | |1200 |

| − | | | + | |2000 |

| − | | | + | |6000kPa |

| + | |7000kPa | ||

| | | | ||

|} | |} | ||

</translate> | </translate> | ||

Revision as of 08:42, 25 December 2017

| |

| Recipe | |

|---|---|

| Created With | Autolathe, Fabricator |

| Cost | 30g Iron, 10g Copper |

| Operation | |

|---|---|

| Construction | |

| Placed with | {{{placed_with_item}}} |

| Placed on | {{{placed_on_grid}}} |

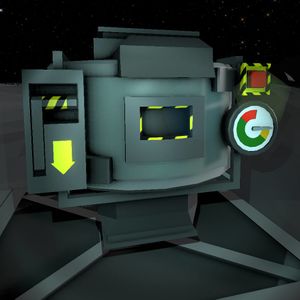

Description

Used to smelt ingots and alloys using an oxygen/volatile gas mix. Ice (Oxite) and Ice (Volatiles) can be manually input directly in the furnace in order to create crude gas mixtures, or to be directly extracted as an easy trick for melting the ice.

Recipes

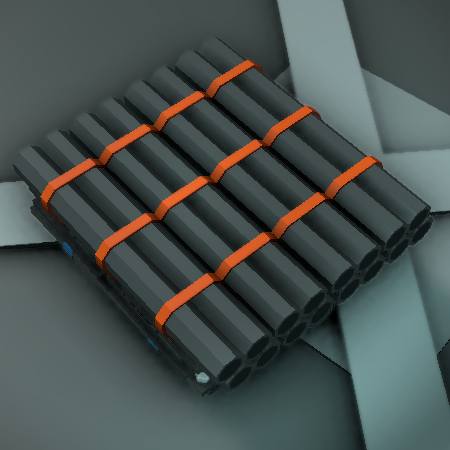

While smelting steel is easily achieved with ice, other recipes usually require a working piping setup. This can be done by separating gases into tanks using atmospheric units and piping individual gases through a mixer and a pressure regulator or a volume pump connected to the furnace input. Output should also be extracted and vented/recycled through a backpressure regulator to keep furnace pressure in check. The optimal gas mix that burns completely is 1 part (33.3%) oxygen to 2 parts (66.6%) volatiles, other mixes would also work but leave you with leftover oxygen or volatiles depending on the percentages used. It could also result in lower temperature if that is desired, but you could also use a volume pump with a lower fuel input setting.

| Metal | Components | Minimum Temperature | Maximum Temperature | Minimal Pressure | Maximum Pressure | Notes |

|---|---|---|---|---|---|---|

| Steel Ingot | 3 iron / 1 coal | 600 | — | 100kPa | — | Can easily be achieved by just dropping 1 oxite and 2 volatiles |

| Electrum Ingot | 1 gold / 1 silver | 700 | 10000 | 800kPa | 2400kPa | |

| Solder Ingot | 1 iron / 1 lead | 300 | 2000 | 300kPa | 3500kPa | |

| Constantan Ingot | 1 copper / 1 nickel | 1000 | 1500 | 100kPa | 10000kPa | |

| Invar Ingot | 1 iron / 1 nickel | 1200 | 2000 | 6000kPa | 7000kPa |