Advanced Furnace

From Unofficial Stationeers Wiki

| |

| Constructing Options | Advanced Furnace |

|---|---|

| Properties | |

| Stacks | No |

| Recipes | |

| Electronics Printer (Tier Two) | 5g Gold, 25g Copper, 30g Steel, 15g Electrum, 8g Solder, 6g Silicon |

| Logic | |

| Item Hash | -616758353 |

| Item Name | ItemKitAdvancedFurnace |

| Logic Classes |

SlotClass.None SortingClass.Kits |

| |

| Operation | |

|---|---|

| Power Usage | 100W |

| Prefab Hash | 545937711 |

| Prefab Name | StructureAdvancedFurnace |

| Construction | |

| Placed with | Kit (Advanced Furnace) |

| Placed on | Small Grid |

| Stage 1 | |

| Next Stage Construction | |

| Constructed with item | 1 x Electronic Parts |

| Deconstruction | |

| Deconstructed with | Hand Drill |

| Item received | Kit (Advanced Furnace) |

| Stage 2 | |

| Next Stage Construction | |

| Constructed with tool | Welding Torch |

| Constructed with item | 5 x Steel Sheets |

| Deconstruction | |

| Deconstructed with | Wire Cutters |

| Item received | 1 x Electronic Parts |

| Stage 3 | |

| Next Stage Construction | |

| Constructed with tool | Screwdriver |

| Deconstruction | |

| Deconstructed with | Angle Grinder |

| Item received | 5 x Steel Sheets |

| Stage 4 | |

| Deconstruction | |

| Deconstructed with | Hand Drill |

Contents

Description[edit]

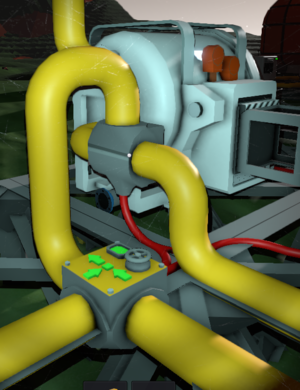

"The advanced furnace comes with integrated inlet and outlet pumps for controlling the unit's internal pressure."

- Stationpedia

The Advanced Furnace is used to create advanced alloys, but can be used to create basic alloys as well. It lends itself to automation. The Maximum pressure for the furnace is 60 MPa before the furnace will, in short order, explode. Adding Hydrocarbons, i.e. coal, will increase the pressure. Contains two embedded volume pumps to control flow in and out, in order to use them, the furnace must be powered, and setting both to zero will put the furnace in a state of quiescence, but the furnace will slowly lose pressure and temperature. The capacity of the furnace is in excess of 5kg of materials so it is possible to make a full 500g ingot of an advanced alloy in one go.

In the early game, a regular Furnace will be easier to make and operate.

Recipes[edit]

| Ingot | Input | Pressure (Pa) | Temperature (K) | Temperature (°C) | |||

|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | ||

| Astroloy | Steel Copper Cobalt |

30 MPa | 40 MPa | 1kK | 100kK | 727°C | 99727°C |

| Hastelloy | Silver Nickel Cobalt |

25 MPa | 30 MPa | 950K | 1kK | 677°C | 727°C |

| Inconel | Gold Nickel Steel |

23.5 MPa | 24 MPa | 600K | 100kK | 327°C | 99727°C |

| Waspaloy | Lead Silver Nickel |

50 MPa | 100 MPa | 400K | 800K | 127°C | 527°C |

| Stellite | Silicon Silver Cobalt |

10 MPa | 20 MPa | 1.8kK | 100kK | 1527°C | 99727°C |

| Update 0.2.2728.13232 - Fri 15/01/2021 /Recipes | |||||||

| NOTE: January StationEARS update reduced the yields from smelting super alloys. Recipes will now return only 1 ingot. | |||||||

See Advanced Furnace/AllRecipes for a complete list

Data Network Properties[edit]

These are all Data Network properties of this device.

Data Parameters[edit]

These are all parameters that can be written with a Logic Writer, Batch Writer, or Integrated Circuit (IC10), and can be read with a Logic Reader, Batch Reader, or Integrated Circuit (IC10).

| Parameter Name | Data Type | Access | Value | Description | ||

|---|---|---|---|---|---|---|

| Power | Boolean | Read

|

0 | Unpowered | Can be read to return if the Advanced Furnace is correctly powered or not, set via the power system, return 1 if powered and 0 if not | |

| 1 | Powered | |||||

| Open | Integer | Read Write

|

||||

| Mode | Integer | Read Write

|

0 | Invalid | The Advanced Furnace's smelting result. | |

| 1 | Valid | |||||

| Error | Boolean | Read

|

0 | 1 if device is in error state, otherwise 0 | ||

| 1 | Error | |||||

| Pressure | Float | Read

|

||||

| Temperature | Integer | Read

|

||||

| Activate | Integer | Read Write

|

||||

| Lock | Boolean | Read Write

|

0 | Unlocked | Disable manual operation of the Advanced Furnace. | |

| 1 | Locked | |||||

| Setting | Integer | Read Write

|

||||

| Reagents | Integer | Read

|

||||

| RatioOxygen | Float | Read

|

0.0 to 1.0 | |||

| RatioCarbonDioxide | Float | Read

|

0.0 to 1.0 | |||

| RatioNitrogen | Float | Read

|

0.0 to 1.0 | |||

| RatioPollutant | Float | Read

|

0.0 to 1.0 | |||

| RatioVolatiles | Float | Read

|

0.0 to 1.0 | |||

| RatioWater | Float | Read

|

0.0 to 1.0 | |||

| Maximum | Float | Read

|

||||

| Ratio | Float | Read

|

0.0 to 1.0 | |||

| On | Boolean | Read Write

|

0 | Off | The current state of the Advanced Furnace. | |

| 1 | On | |||||

| RequiredPower | Integer | Read

|

||||

| RecipeHash | Integer | Read

|

||||

| ClearMemory | Integer | Write

|

||||

| ExportCount | Integer | Read

|

||||

| ImportCount | Integer | Read

|

||||

| TotalMoles | Float | Read

|

||||

| RatioNitrousOxide | Float | Read

|

0.0 to 1.0 | |||

| PrefabHash | Integer | Read

|

||||

| SettingInput | Integer | Read Write

|

||||

| SettingOutput | Integer | Read Write

|

||||

| Combustion | Boolean | Read

|

0 or 1 | |||

| RatioLiquidNitrogen | Float | Read

|

0.0 to 1.0 | |||

| RatioLiquidOxygen | Float | Read

|

0.0 to 1.0 | |||

| RatioLiquidVolatiles | Float | Read

|

0.0 to 1.0 | |||

| RatioSteam | Float | Read

|

0.0 to 1.0 | |||

| RatioLiquidCarbonDioxide | Float | Read

|

0.0 to 1.0 | |||

| RatioLiquidPollutant | Float | Read

|

0.0 to 1.0 | |||

| RatioLiquidNitrousOxide | Float | Read

|

0.0 to 1.0 | |||

| ReferenceId | Integer | Read

|

||||

| RatioHydrogen | Float | Read

|

0.0 to 1.0 | |||

| RatioLiquidHydrogen | Float | Read

|

0.0 to 1.0 | |||

| RatioPollutedWater | Float | Read

|

0.0 to 1.0 | |||

| NameHash | Integer | Read

|

||||

Data Slots[edit]

These are all parameters, that can be read with a Slots Reader. The outputs are listed in the order a Slots Reader's "VAR" setting cycles through them.

| Number | Name | Description |

|---|---|---|

| 0? | Import | Import slot. |

| 1? | Export | Export slot. |

| Name | Data Type | Description |

|---|---|---|

| OccupantHash | ||

| Occupied | Boolean | Returns whether the slot occupied. (0 for no, 1 for yes). |

| PrefabHash | ||

| Quantity | ||

| Class | ||

| Damage | ||

| MaxQuantity |

Usage[edit]

While it is possible to operate the advanced furnace similar to a regular furnace (add fuel, ignite, add ore), the most common setups for advanced furnaces are:

- ice only smelting

- fuel mixing

- hot and cold mixing

Ice only smelting[edit]

In this setup ice is fed into the input slot of the furnace prior to loading ores for smelting. [1]

| Alloy | Ingredients | Chunks | Temperature | Pressure |

|---|---|---|---|---|

| Stellite | Silver Ore Cobalt Ore Silicon Ore |

Volatiles Oxite |

1.82 kK | 13.6 MPa |

| Inconel | Gold Ore Nickel Ore Steel Ingot |

Volatiles Oxite |

1.78 kK | 24.2 MPa +++ |

| Astroloy | Steel Ingot Copper Ore Cobalt Ore |

Volatiles Oxite |

1.92 kK | 33 MPa |

| Hastelloy | Silver Ore Nickel Ore Cobalt Ore |

Volatiles Oxite ^^^ |

997 K | 27.3 MPa |

| Waspaloy | Lead Ore Silver Ore Nickel Ore |

Volatiles Oxite ^^^ |

691 K | 50.2 MPa |

Note that at least one gas pipe must be connected to both the input and output gas lines to avoid error conditions.

+++ For Inconel the mixture pressure will overshoot the range slightly, either make the alloy when the pressure rises into the range, or a short wait will be necessary in order for the pressure to drop back into range.

^^^ The excess Oxites are necessary in order to limit the temperature of the mixture, however they can be substituted with other inert gasses.

Gaseous Fueling[edit]

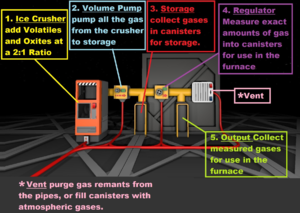

In this setup fuel is pumped into the furnace from either pre-measured canisters or pumped into the furnace in measured amounts. Fuel can be either a 2:1 Volatile to O2 mixture, raw gases from Volatile and Oxite ices, or Superfuel. Raw gases can be collected by putting Volatile Ice and Oxites into an Ice crusher, or by melting the gases in an enclosed area and pumping the gases into a canister with an active vent. Superfuel can be made by collecting N2O and mixing it with Volatiles at a 1:1 Ratio. Raw gasses made from ices will have a ratio of 3.6% Nitrogen, 32.7% Oxygen, and 63.7% Volatiles, and the Volatile to Oxygen ratio will be 1.95:1 instead of 2:1, but it will burn adequately well.

Do not degas the ores, Stellite, Hastelloy and Waspaloy all rely on the nitrous oxide produced from the silver ore and lead ore used in their production. Do not substitute an ingot for an ore. Feed the ores into the furnace in the listed order. Use the listed amount of ores, using less ore or more ore will result in an different pressure and temperature.

| Canister Pressure @ 0°C | Gases | Ingredients | Temperature | Pressure | Alloy |

|---|---|---|---|---|---|

| 3,600 KPa Fuel |

62.7 Mols Volatiles 32.1 Mols Oxygen |

Silver Ore Cobalt Ore Silicon Ore |

1.84 kK | 15.2 MPa | Stellite |

| (2x) 8,400 KPa Fuel |

286 Mols Volatiles 146 Mols Oxygen |

Gold Ore Nickel Ore Steel Ingot |

1.75 kK | 24.1 MPa +++ | Inconel |

| (3x) 7,225 KPa Fuel |

371 Mols Volatiles 190 Mols Oxygen |

Steel Ingot Copper Ore Cobalt Ore |

1.89 kK | 30.8 MPa | Astroloy |

| 8,500 KPa Fuel (8x) 8,600 KPaPressurant |

146 Mols Volatiles 74.8 Mols Oxygen 1,900 Mols Pressurant ^^^ |

Silver Ore Nickel Ore Cobalt Ore |

1.02 kK | 27.6 MPa | Hastelloy |

| (3x) 7,333 KPa Fuel (24x) 9,750 KPaPressurant |

376 Mols Volatiles 192 Mols Oxygen 6,800 Mols Pressurant ^^^ |

Lead Ore Silver Ore Nickel Ore |

683 K | 51.4 MPa | Waspaloy |

+++ For Inconel the mixture pressure will overshoot the range slightly, either make the alloy when the pressure rises into the range, or a short wait will be necessary in order for the pressure to drop back into range.

^^^ These recipes use CO2 @ 0°C as a pressurant. Other pressurants such as Nitrogen, Pollutants, and Oxygen are possible, but they may result in different outcomes.

Fuel mixing[edit]

In this setup, the furnace's input is connected to a gas mixer to provide fuel, and often a dilutant (used to increase the pressure without spending extra fuel). The Furnace temperature and pressure math article contains formulas useful for crafting recipes to hit temperature and pressure targets.