Kit (Counterflow Heat Exchanger)

From Unofficial Stationeers Wiki

| Properties | |

|---|---|

| Stacks | No |

| Paintable | Yes |

| Recipe | |

| Created With | Hydraulic Pipe Bender Tier two |

| Cost | 10g Steel, 10g Invar |

| Logic | |

| Item Hash | 6361127870 |

| Item Name | ItemKitPassthroughHeatExchanger |

| Operation | |

|---|---|

| Prefab Hash | Varies |

| Prefab Name | Varies |

| Construction | |

| Placed with | Kit (Counterflow Heat Exchanger) |

| Placed on | Small Grid |

| Stage 1 | |

| Next Stage Construction | |

| Constructed with tool | Welder |

| Constructed with item | Steel Sheets x1 |

| Deconstruction | |

| Deconstructed with | Hand Drill |

| Item received | Kit (Counterflow Heat Exchanger) |

| Stage 2 | |

| Deconstruction | |

| Deconstructed with | Wrench |

| Item received | Steel Sheets x1 |

Description

Exchange heat from one pipe network to another. By drawing down the pressure of the outputs with a pump or regulator and regulating input pressures, the temperatures of the two counterflowing networks can be effectively exchanged.

Balancing the throughput of both inputs is key to creating a good exchange of temperatures.

- Stationpedia

Swaps the temperature of two input fluids, how well it does this depends on the relative flow rate of each input.

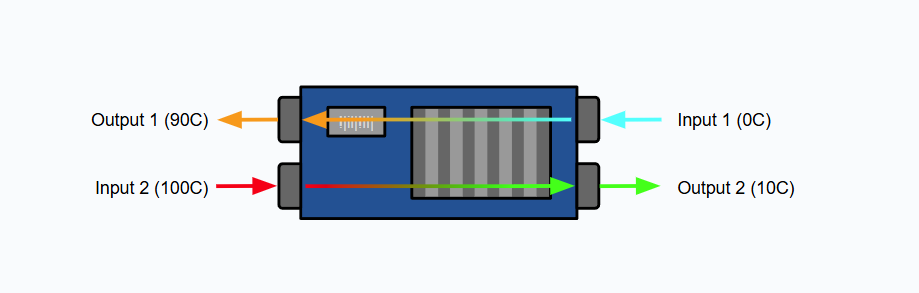

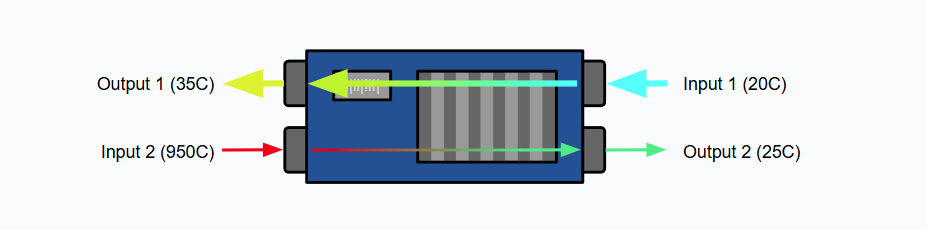

Perfect temperature exchange is thermodynamically impossible, and doesn't happen in stationeers either. The two connections on the top are part of network 1, and the two on the bottom are part of network 2. A meter on the side displays the heat exchange rate in joules per tick as well as the throughput of input 1 and 2 in moles per tick.

Usage

1. The intended use case for a counterflow heat exchanger is when you have two fluids with the same thermal mass flowing at the same rate in opposite directions. In this condition the heat exchanger will swap the temperatures of the two input fluids and send them to their outputs, possibly off by a few degrees. See first example.

- This can be useful for phase change cooling loops to warm the evaporated phase before it is condensed and to cool the condensed phase before it is evaporated, improving efficiency.

2. They are also commonly used as a more effective heat exchanger that can take greater advantage of a coolant's thermal energy and keep a consistant temperature in a pipe network. In this case fluid properties and flow rate are not the same.

- Say you have a 20C coolant flow trying to cool down a trickle of hot waste gas down to 20C. As long as the flow (or thermal mass) of the coolant is much greater than the waste gas, the output temperature of the waste gas will always be very close to the coolant. If using the Direct heat exchanger instead, the temperature would spike every time more hot gas was introduced to the network before cooling down to the temperature of the coolant again. See second example.

Setup

- Example temperature differences are exaggerated, usually the input 1 and output 2 temperatures get very close, within tenths of a degree.

Example showing how the two inputs can effectively exchange their temperatures in ideal conditions.

Example showing how the initial temperature of network 1 determines the output temperature of network 2, when flowrate / thermal mass is skewed heavily in favor of network 1.

Notes

- It has no logic port

- Requires frame support

- In older versions, heat exchangers had 2 inputs and 2 outputs intended for active liquid flow, but the heat swapping mechanic wasn't fleshed out. This eventually became the counterflow heat exchanger after the Airflow update.

Prefab Information

| Prefab Hash | Prefab Name | |

|---|---|---|

| Gas to Gas | -1674187440 | StructurePassthroughHeatExchangerGasToGas |

| Gas to Liquid | 1928991265 | StructurePassthroughHeatExchangerGasToLiquid |

| Liquid to Liquid | -1472829583 | StructurePassthroughHeatExchangerLiquidToLiquid |