Kit (Pressure Regulator)

From Unofficial Stationeers Wiki

| |

| Constructing Options | Pressure Regulator, Back Pressure Regulator, Pressurant Valve, Purge Valve |

|---|---|

| Properties | |

| Stacks | Yes (5) |

| Recipes | |

| Hydraulic Pipe Bender | 5g Iron, 1g Gold, 2g Copper |

| Logic | |

| Item Hash | 1181371795 |

| Item Name | ItemKitRegulator |

| Logic Classes |

SlotClass.None SortingClass.Kits |

Contents

Description[edit]

Pressure Regulators are useful components in Atmospherics systems, designed to manage gas flow and pressure.

This kit can create four devices: the Pressure Regulator, Back Pressure Regulator, Pressurant Valve, and Purge Valve. Use left-click while in active hands to place. Scroll to switch between variants.

Much like most other similar devices and components, all Pressure Regulator units operate as an interactive cross-feed between the two pipe networks without being a part of either - they do not have their individual content and do not transfer anything beyond what their functionality allows. When unpowered, Pressure Regulators do not allow any transfer between the networks at all. If either side of the device is missing the pipe network connection, it will blink to indicate an error and will not function.

All Pressure Regulator devices have a flat power demand, that is unaffected by the efficiency of the process, or whether any actual work is being done or not.

Recipes[edit]

| Manufactory | Materials | Time | Energy |

|---|---|---|---|

| Hydraulic Pipe Bender | 5g Iron, 1g Gold, 2g Copper | 5 | 500 |

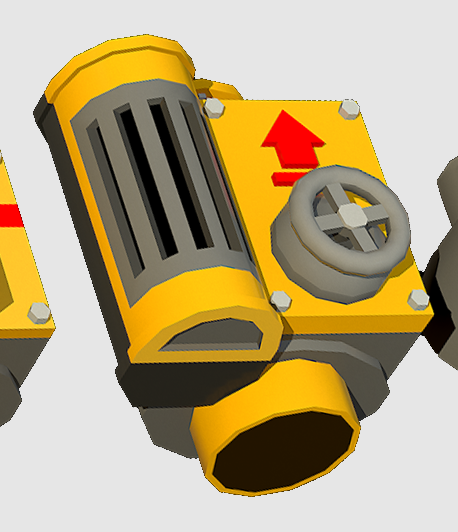

Pressure Regulator[edit]

| |

| Operation | |

|---|---|

| Power Usage | 100W |

| Prefab Hash | 209854039 |

| Prefab Name | StructurePressureRegulator |

| Construction | |

| Placed with | Kit (Pressure Regulator) |

| Placed on | Small Grid |

| Stage 1 | |

| Deconstruction | |

| Deconstructed with | Hand Drill |

| Item received | Kit (Pressure Regulator) |

Description[edit]

Controlling the flow of gas between two pipe networks, pressure regulators shift gas until a set pressure on the outlet side is achieved, or the gas supply is exhausted. The back pressure regulator, by contrast, will only operate when pressure on the intake side exceeds the set value. With a max pressure of over 20,000kPa, it requires power to operate.

- Stationpedia

The standard Pressure Regulator is an active powered device for controlled transfer of substances between the two pipe networks. Pressure Regulator will use the gas from Input pipe network to pressurize the Output pipe network until a target pressure defined by the valve setting is reached or exceeded, or unless the input pipe runs dry. When being placed, hologram indicators will display the Input pipe arrow inward, the Output pipe arrow outward, and the power socket on its side. It has a pressure control valve, which defines the target pressure.

The most common use for a standard Pressure Regulator is to place one ahead of a Gas Tank Storage unit to safely fill the inserted Gas Canister or Gas Canister (Smart) with gas input without overpressurizing it. Similar principle can be used to maintain the desired pressure level in any pipe network or room.

The maximum pressure setting is 60795 kPa - a critical pressure limit for a pipe network before it begin to take damage.

To calculate the moles per tick, use the following equation: n = (P * V) / (R * T)

Where:

- P = Min(Input pressure, 101.325)

- V = (OutputPipeVolume / InputPipeVolume) * 100

- n = Moles per tick

- R = Gas constant (8.3144)

- T = Input temperature

Data Network Properties[edit]

These are all Data Network properties of this device.

Data Parameters[edit]

These are all parameters that can be written with a Logic Writer, Batch Writer, or Integrated Circuit (IC10), and can be read with a Logic Reader, Batch Reader, or Integrated Circuit (IC10).

| Parameter Name | Data Type | Access | Value | Description | ||

|---|---|---|---|---|---|---|

| Power | Boolean | Read

|

0 | Unpowered | Can be read to return if the Pressure Regulator is correctly powered or not, set via the power system, return 1 if powered and 0 if not | |

| 1 | Powered | |||||

| Error | Boolean | Read

|

0 | 1 if device is in error state, otherwise 0 | ||

| 1 | Error | |||||

| Lock | Boolean | Read Write

|

0 | Unlocked | Disable manual operation of the Pressure Regulator. | |

| 1 | Locked | |||||

| Setting | Integer | Read Write

|

0.0 to 60795.0 | |||

| Maximum | Float | Read

|

||||

| Ratio | Float | Read

|

0.0 to 1.0 | |||

| On | Boolean | Read Write

|

0 | Off | The current state of the Pressure Regulator. | |

| 1 | On | |||||

| RequiredPower | Integer | Read

|

||||

| PrefabHash | Integer | Read

|

||||

| ReferenceId | Integer | Read

|

||||

| NameHash | Integer | Read

|

||||

Back Pressure Regulator[edit]

| File:StructureBackPressureRegulator.png | |

| Operation | |

|---|---|

| Power Usage | 100W |

| Prefab Hash | -1149857558 |

| Prefab Name | StructureBackPressureRegulator |

| Construction | |

| Placed with | Kit (Pressure Regulator) |

| Placed on | Small Grid |

| Stage 1 | |

| Deconstruction | |

| Deconstructed with | Hand Drill |

| Item received | Kit (Pressure Regulator) |

Description[edit]

Unlike the Pressure Regulator, which closes when the input exceeds a given pressure, the back pressure regulator opens when input pressure reaches a given value.

- Stationpedia

The Back Pressure Regulator is an active powered device for controlled transfer of substances between the two pipe networks. The Back Pressure Regulator will only pass through gases when the pressure on its intake side exceeds the set value. In other words, it prevents the input network from exceeding the set pressure limit by diverting the excess into the output network. When being placed, hologram indicators will display the Input pipe arrow inward, the Output pipe arrow outward, and the power socket on its side. It has a pressure control valve, which defines the target pressure.

The most common use for a Back Pressure Regulator is as a failsafe mechanism, that can prevent a given pipe network from being overpressurized by a temperate output of other devices, diverting the gas into an arbitrary waste network. Similarly, it can be used to control the pressure within a room, where pressure can fluctuate due to increase in temperature, or has an active gas input to circulate an appropriate atmosphere. However, its low flow rate makes it not suitable for being used as an emergency dump valve in its own right, where a logic-controlled Active Vent or Turbo Volume Pump (Gas) would be more appropriate.

The maximum pressure that can be set is 60795 kPa - a critical pressure limit for a pipe network before it begin to take damage.

To calculate the moles per tick, use the following equation: n = (P * V) / (R * T)

Where:

- P = Min(Input pressure, 101.325)

- V = 100

- n = Moles per tick

- R = Gas constant (8.3144)

- T = Input temperature

Data Network Properties[edit]

These are all Data Network properties of this device.

Data Parameters[edit]

These are all parameters that can be written with a Logic Writer, Batch Writer, or Integrated Circuit (IC10), and can be read with a Logic Reader, Batch Reader, or Integrated Circuit (IC10).

| Parameter Name | Data Type | Access | Value | Description | ||

|---|---|---|---|---|---|---|

| Power | Boolean | Read

|

0 | Unpowered | Can be read to return if the Back Pressure Regulator is correctly powered or not, set via the power system, return 1 if powered and 0 if not | |

| 1 | Powered | |||||

| Error | Boolean | Read

|

0 | 1 if device is in error state, otherwise 0 | ||

| 1 | Error | |||||

| Lock | Boolean | Read Write

|

0 | Unlocked | Disable manual operation of the Back Pressure Regulator. | |

| 1 | Locked | |||||

| Setting | Integer | Read Write

|

0.0 to 60795.0 | |||

| Maximum | Float | Read

|

||||

| Ratio | Float | Read

|

0.0 to 1.0 | |||

| On | Boolean | Read Write

|

0 | Off | The current state of the Back Pressure Regulator. | |

| 1 | On | |||||

| RequiredPower | Integer | Read

|

||||

| PrefabHash | Integer | Read

|

||||

| ReferenceId | Integer | Read

|

||||

| NameHash | Integer | Read

|

||||

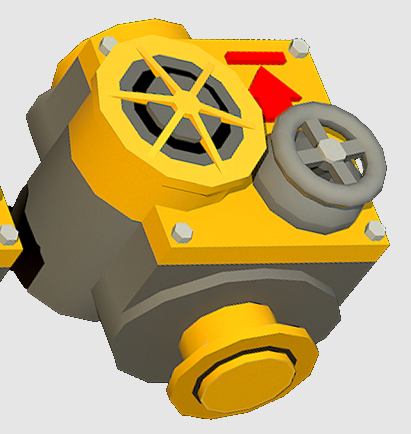

Pressurant Valve[edit]

| |

| Operation | |

|---|---|

| Power Usage | 100W |

| Prefab Hash | 23052817 |

| Prefab Name | StructurePressurantValve |

| Construction | |

| Placed with | Kit (Pressure Regulator) |

| Placed on | Small Grid |

| Stage 1 | |

| Deconstruction | |

| Deconstructed with | Hand Drill |

| Item received | Kit (Pressure Regulator) |

Description[edit]

Pumps gas into a liquid pipe in order to raise the pressure

- Stationpedia

The Pressurant Valve is an active powered device for controlled transfer of substances between the two pipe networks. When active, Pressurant Valve will pump the gas from Input pipe network into the Output liquid pipe network until the target pressure defined by the valve setting is reached or exceeded, or unless the input pipe runs dry. When being placed, hologram indicators will display the Input pipe arrow inward, the Output pipe arrow outward, and the power socket on its side. It has a pressure control valve, which defines the target pressure.

Pressurant Valve is conventionally used for maintaining the liquid state of a contained substance (such as water), that would otherwise evaporate in absense of the background pressure. It can also be utilized to actively condense a cooled gas into a liquid by injecting a pressurant gas, or inversely to force the liquid to evaporate by injecting a heated gas and raising the temperature without the dedicated Pipe Heater (Liquid). The more efficient use of these principles require the knowledge of the gas phase change diagram, to pick an appropriate gas input, its temperature, and the target pressure, the combination of which achieves the desired final result.

Data Network Properties[edit]

These are all Data Network properties of this device.

Data Parameters[edit]

These are all parameters that can be written with a Logic Writer, Batch Writer, or Integrated Circuit (IC10), and can be read with a Logic Reader, Batch Reader, or Integrated Circuit (IC10).

| Parameter Name | Data Type | Access | Value | Description | ||

|---|---|---|---|---|---|---|

| Power | Boolean | Read

|

0 | Unpowered | Can be read to return if the Pressurant Valve is correctly powered or not, set via the power system, return 1 if powered and 0 if not | |

| 1 | Powered | |||||

| Error | Boolean | Read

|

0 | 1 if device is in error state, otherwise 0 | ||

| 1 | Error | |||||

| Lock | Boolean | Read Write

|

0 | Unlocked | Disable manual operation of the Pressurant Valve. | |

| 1 | Locked | |||||

| Setting | Integer | Read Write

|

0.0 to 60795.0 | |||

| Maximum | Float | Read

|

||||

| Ratio | Float | Read

|

0.0 to 1.0 | |||

| On | Boolean | Read Write

|

0 | Off | The current state of the Pressurant Valve. | |

| 1 | On | |||||

| RequiredPower | Integer | Read

|

||||

| PrefabHash | Integer | Read

|

||||

| ReferenceId | Integer | Read

|

||||

| NameHash | Integer | Read

|

||||

Purge Valve[edit]

| |

| Operation | |

|---|---|

| Power Usage | 100W |

| Prefab Hash | -737232128 |

| Prefab Name | StructurePurgeValve |

| Construction | |

| Placed with | Kit (Pressure Regulator) |

| Placed on | Small Grid |

| Stage 1 | |

| Deconstruction | |

| Deconstructed with | Hand Drill |

| Item received | Kit (Pressure Regulator) |

Description[edit]

"Allows for removal of pressurant gas and evaporated liquids from a liquid pipe. Similar in function to a Back Pressure Regulator the Purge Valve moves gas from the input liquid pipe to the output gas pipe aiming to keep the pressure of the input at the target setting."

- Stationpedia

Purge Valve is an active powered device for controlled transfer of substances between the two pipe networks. Purge Valve will drain the gas from Input liquid pipe network and transfer it to the Output gas pipe network until a pressure limit defined by the valve setting is reached on Input network. Setting the pressure limit to 0 will pump the gases out completely, leaving only the liquids behind. When being placed, hologram indicators will display the Input liquid pipe arrow inward, the Output gas pipe arrow outward, and the power socket on its side. It has a pressure control valve, which defines the pressure limit.

Purge Valves are often used to collect a substance evaporated from its liquid state (such as Nitrous Oxide, often stored in its liquid form) before its practical use. Other than that, it can be utilized to remove any undesired gas constituents from a liquid pipe. Used in conjunction with a Pressurant Valve, Purge Valve can be used to precisely control the pressure within a liquid pipe network for complex phase change operations.

NOTE: Since Purge Valve drains gas pressure from the liquid pipe and raises it in the gas pipe, this inevitably causes the liquids to begin evaporating. The evaporated liquid then may leak through the Purge Valve and inadvertedly condense into a liquid again, meeting the gas pressure it have just lost, which may cause the pipes to flood and burst. Make sure to backup the Purge Valve with a Condensation Valve going the opposite way to drain the liquid back into the liquid pipe, or maintain a safe pressure level and lower temperature in the liquid pipe to prevent that.

Data Network Properties[edit]

These are all Data Network properties of this device.

Data Parameters[edit]

These are all parameters that can be written with a Logic Writer, Batch Writer, or Integrated Circuit (IC10), and can be read with a Logic Reader, Batch Reader, or Integrated Circuit (IC10).

| Parameter Name | Data Type | Access | Value | Description | ||

|---|---|---|---|---|---|---|

| Power | Boolean | Read

|

0 | Unpowered | Can be read to return if the Purge Valve is correctly powered or not, set via the power system, return 1 if powered and 0 if not | |

| 1 | Powered | |||||

| Error | Boolean | Read

|

0 | 1 if device is in error state, otherwise 0 | ||

| 1 | Error | |||||

| Lock | Boolean | Read Write

|

0 | Unlocked | Disable manual operation of the Purge Valve. | |

| 1 | Locked | |||||

| Setting | Integer | Read Write

|

0.0 to 60795.0 | |||

| Maximum | Float | Read

|

||||

| Ratio | Float | Read

|

0.0 to 1.0 | |||

| On | Boolean | Read Write

|

0 | Off | The current state of the Purge Valve. | |

| 1 | On | |||||

| RequiredPower | Integer | Read

|

||||

| PrefabHash | Integer | Read

|

||||

| ReferenceId | Integer | Read

|

||||

| NameHash | Integer | Read

|

||||