Temperature independent fuel mixing

From Unofficial Stationeers Wiki

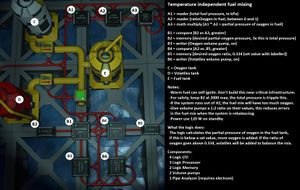

When fuel is made with a Pipe Gas Mixer, the desired ratio will be wrong if the gases have different temperatures. By using volume pumps and some logic circuits, the correct 2:1 fuel mix can be obtained without waiting for the temperature to equalize.

This setup measures the total fuel pressure and the ratio of oxygen in the fuel, these values are then multiplied to calculate the partial oxygen pressure. Since the mixed gas has a uniform temperature, this calculated value is indirectly a measure of how many moles of oxygen there are in the tank. The partial oxygen pressure is then used to decide if more oxygen should be added or not, this also doubles as a safety mechanism, since it gives the player some control over the max pressure in the fuel tank (which is tripple this value). Volatiles are added automatically whenever the ratio of oxygen in the fuel mix becomes too high. A problem with this setup is that it will continue to add oxygen which if the volatiles run out, which will ruin the fuel ratio. This can be fixed either by adding valves (infront of the volume pumps so they don't blow the pipes) for manual control or by adding more circuits.

Components

- Gas pipes

- Gas storage

- Wires

- 4 Logic I/O

- 3 Logic Processor

- 2 Logic Memory

- 2 Volume pumps

- 1 Pipe Analyzer (requires electrum)

Setup

- Connect volume pumps from O2/H2 respectively leading towards the fuel side

- Connect the pipe analyzer on the fuel side

- Optional: Use a Power Area Control or Transformer to isolate the logical components to their own network. This also makes it easy to shut off the system.

- Place logical components

- A1: Reader for pipe analyzer, total pressure (in KPa)

- A2: Reader for pipe analyzer, ratioOxygen (between 0 and 1)

- A3: Math multiplier, A1*A2 (this is the partial oxygen pressure in the fuel tank)

- B1: Compare, B2 vs. A3, greater

- B2: Memory, 2000 (desired partial oxygen pressure, 3x this will be the total pressure)

- B3: Writer for Oxygen volume pump, on

- B4: Compare, A2 vs. B5, greater

- B5: Memory, 0.334 (use Labeller to set this value)

- B6: Writer for Volatiles volume pump, on

Notes

- Warm fuel can self ignite. Don't mix fuel near critical infrastructure.

- For safety, set the desired partial oxygen pressure to 2000 max, the total pressure will be tripple this value in kPa.

- If the system runs out of volatiles, the fuel mix will still be fed oxygen.

- If the system runs out of oxygen, the system will stop adding volatiles.

- Give volume pumps a 1:2 ratio on their values, this reduces errors in the fuel mix when the system is rebalancing.

- Power use 120 W on standby